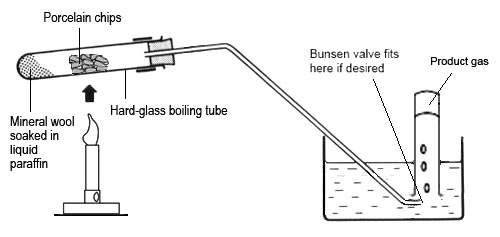

1- Heat the hydrocarbon (e.g. paraffin).

2- After a few seconds, move the Bunsen burner to heat the silica/aluminium catalyst

3- Alternate between the two until the paraffin vaporises and the catalyst glows red

4- The heated paraffin vapour cracks as it passes over the heated catalyst

5- small alkanes collect at the end of the boiling tube, while alkene gases travel down the delivery tube

6- The alkenes are collected through water using a glass jar

In industry, vapourised hydrocarbons are passed over a powdered catalyst at about 600-700°C. silica and aluminium are used as catalysts.

Notes credit: CGP

No comments:

Post a Comment